Pressure Switchover series M 470 C PVC provides an uninterrupted supply of chlorine gas to the system. It assures safe and reliable switching between two chlorine gas sources.

GENERAL

The Pressure Switchover series M 481 C provides an uninterrupted supply of liquid or gas chlorine to the system. It assures safe and reliable switching between two chlorine gas or liquid sources.

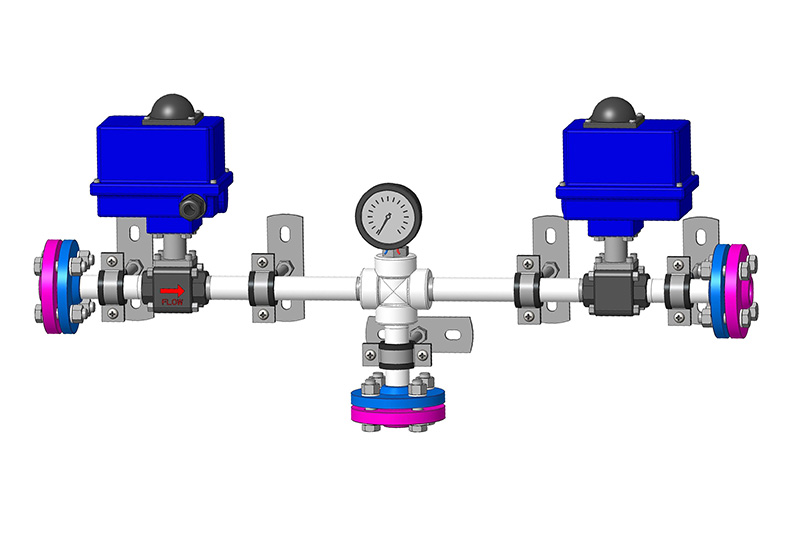

Automatic pressure switchover consists of:

- pressure switches

- motorized ball valves

- manifolds and bypass valves

- connection flanges

There are two versions of the M 481 C pressure switchover available:

M 481 C/1—with one pressure probe; controls pressure to consumption

M 481 C/2—with two pressure probes; controls the source pressure (pressure of the chlorine supply)

OPERATION PRINCIPLE

Pressure switchover unit consists of two independent, electrical motor-driven ball valves, depending on version, one or two pressure probes and microprocessor controlled control panel.

Under normal operating conditions, there is always an excess pressure of approximately 6 to 7 bar (at 20°C) in chlorine cylinders or containers (drums).

This pressure drops when chlorine is consumed. The pressure probe senses the pressure drop and the control panel initiate the motor valves to switch to the full chlorine source.

On the control panel, the operator can check the status of the operation of the pressure switchover. Depending on the version, different alarms are indicated. In case of switchover failure, valves can be closed or opened manually on the motorized ball valves.